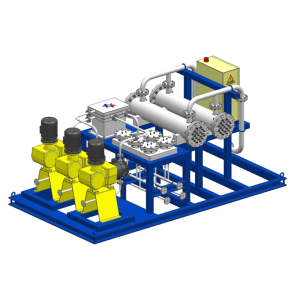

Udstyrets navn: MRE Bottom-entry High shear Dispersing Emulsifier

Introduktion til udstyr:

MRE usually installed in the bottom, and do batch processing, it has same working principal as MRH, the high line speed generated by the high-speed rotation of the rotor enables the dispersion, shearing, crushing, emulsification and other effects of the material under the combined forces in the narrow gap between the rotor and the stator. MRE series adopts the bottom installation method, which can meet the requirements of the lower liquid level, and also has the bottom circulation form. The effect is better for the materials with easy precipitation, large specific gravity, high viscosity and large particles.

Udstyr Funktioner:

Bottom entry, lower liquid level, large working capacity

Same power, higher rotation speed, higher shear force

Bottom processing, meget målrettet, intet dødt hjørne

Flere tandformer af rotor/ statorstruktur kan tilpasses til forskellige driftsforhold

Tovejssugning, stabil drift

Velegnet til forskellige driftsforhold: høj temperatur, højt tryk, eksplosionssikker, korrosionsbestandig og reaktion mv..

Programmer:

MRE er meget udbredt i kosmetik, mad, medicin og kemiske og fine kemiske industrier til at håndtere homogenisering, dispersion, emulgering, crushing, Opløsnings- og limningsprocesser.

Såsom

Fløde, mælkedrikke, saft

Kosmetisk creme, Tandpasta

Vandemulsion, suspension agent

Medicinsk fedtemulsion, Vaccine

Kolloid opløsning, polymeremulgering

Pigmenter, dyes, chlorine cakes broken

Vigtigste parametre

| Model | Power(kW) | Rotate speed(rpm) | Working capacity(L) |

| MRE100/05 | 1.5 | 2900 | 5-50 |

| MRE200/10 | 2.2 | 2900 | 30-100 |

| MRE300/15 | 5.5-7.5 | 2900 | 100-800 |

| MRE400/20 | 11-15 | 2900 | 300-2000 |

| MRE400/25 | 22-30 | 1470/2900 | 800-4000 |

| MRE500/30 | 37 | 1470/2900 | 800-5000 |

| MRE500/35 | 45-55 | 1470 | 1000-7000 |

Tegn:

Data baseret på vandmedium.

Kontakt Moarey teknisk ingeniør for mere detaljerede oplysninger og applikationsdata.