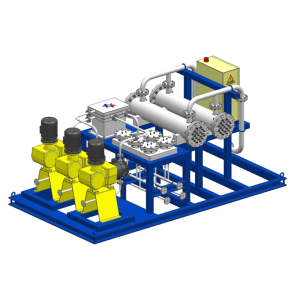

Nome dell'apparecchiatura: MRX-T Sistema di dosaggio in linea solido-liquido

Introduzione all'attrezzatura:

MRX-V è una nuovissima soluzione sistematica per l'iniezione di polvere, miscelazione e dissoluzione della polvere. Utilizza il potente vuoto generato dal proprio principio del getto per inalare uniformemente e rapidamente la polvere solida nel tubo del getto, instant contact with the liquid and wetting, e poi nella camera di lavoro ad alto taglio, through high-frequency shear force by rotor/stator, the solid powder is fully dispersed or completely dissolved. MRX-V series adopts “V” type powder hopper design, suitable for multi-bag, multi-type powder inline dispersion or dissolution, higher production efficiency.

Equipment Features:

- “V” type hopper design, faster powder suction, maximum powder input up to 200kg/min

- Easily solve high-viscosity, easily-swollen powders such as CMC and xanthan

- Can achieve normal or lowertemperature powder dissolution, lower energy consumption

- Easy to clean, simple to meet CIP/SIP operation, in compliance with hygienic design standards and specifications

- Convenient artificial dusting, labor saving, inline mixing powder, higher efficiency

- Design modulare, smaller footprint, easy installation and maintenance

Applicazione:

MRX-V is widely used in the food, pharmaceutical, chemical and fine chemical industries, processing powder liquid dispersion, mixing, depolymerization, dissolving, plastic and other technological processes.

Come

Inline ingredient dissolution of reduced milk, fruit milk, yogurt

Supersaturation of sugar

Dissolution of CMC, carrageenan, pectin, and so on.

Inline homogenization of cereals/water, starch/water

Concentrated tea powder, concentrated juice online ingredients

Dispersion and Mixing of Ultrafine Powders: Titanium Dioxide, Pigments, Bentonite, Kaolin, Talc, Polvere di calce, and so on.